Bat rolling machines are used to compress the fibers in a baseball or softball bat, making it more flexible and increasing its performance.

These machines can be quite expensive, but with some basic knowledge and tools, you can easily build your own DIY bat-rolling machine.

I will guide you through this blog.

What Is a Bat Rolling Machine?

So, what even is a bat-rolling machine? It’s like a secret weapon for baseball and softball lovers.

Put simply, it’s something that makes your composite bats better. How does it work? It presses down on the fibers of your bat.

Think of it like breaking in a new pair of shoes but for your bat. The best part? This thing will give you some serious improvements on the field. When you hit the ball, it’ll go flying.

To be honest, these things can be costly, though creating one at home is definitely an option if you’re down to do some DIY.

During the rolling, the process goes through heated bat rolling. Also, the more you use your composite baseball bat, the more it will be heated by itself.

By the way, using a bat rolling machine for bat rolling is helpful in significant ways. The most significant advantage is that it breaks in the composite bats in a faster way.

Materials Needed to Build a Bat Rolling Machine

To build your own DIY bat rolling machine, you will need the following materials:

- Steel or Aluminum: These will be used for the frame and shell of the machine. Alternatively, you can also use metal plates for structural support.

- Rollers or Rolling Pins: These are vital for the rolling process. The bats will be rolled between these to compress the fibers.

- Bearings: Both ball bearings and thrust bearings are needed. These will allow the rollers to move smoothly during operation.

- Shafts: These will be used for connecting the rollers.

- Fasteners: Nuts, bolts, and screws will secure all components together.

- Handles: These will allow the user to control the machine efficiently.

- Gloves: Essential for hand protection while operating the machine.

- Safety Glasses: These will protect your eyes during the machine’s operation.

- Lubricants: These will be used for the bearings to ensure their smooth operation.

- Paint and finishing materials (for aesthetic purposes).

How to Build a Bat Rolling Machine: Step-by-Step

Step 1: Construct the Main Structure

The backbone of your DIY bat rolling machine is its shell, which provides the structural integrity for the entire apparatus.

Start by measuring and cutting your chosen material, either steel or aluminum, to the desired dimensions.

Weld these pieces together to create the base and sides of the machine. Keep in mind that once this all-welded design is complete, modifications and repairs can be challenging due to its rigid structure.

Step 2: Build the Top Carriage

The top carriage supports the upper rollers, playing a critical role in the bat rolling function.

Craft this carriage using either aluminum or steel for strength and durability.

This component will also house the shaft that holds the bearings responsible for smooth roller rotation.

Step 3: Install the Handles

Proper handle placement is crucial for the bat rolling machine’s efficient operation.

One handle should be positioned above the top carriage, allowing the user to apply and maintain pressure during the rolling process.

The second handle, intended for rotating the rollers, should be conveniently located for comfortable and easy operation.

Step 4: Assembly

Once all individual components are ready, it’s time for assembly.

Connect the rollers to the shafts, ensuring the ball bearings and thrust bearings are in place for smooth operation.

Secure all parts using the necessary fasteners — nuts, bolts, and screws. Don’t forget to lubricate the bearings for smooth operation.

Step 5: Finishing Touches

To finish, you can apply paint or other finishing materials to enhance the machine’s aesthetic appeal.

Remember, safety is paramount — always use gloves, safety glasses, and ear protection when operating your DIY bat rolling machine.

Cost And Time

Building your own DIY bat rolling machine has a big cost advantage compared to buying one ready-made.

Depending on the materials you use and where you get them, it can cost anywhere from $100 to $300. The main expense is getting top-notch rollers, bearings, shafts, and frame materials.

But here’s the thing – it does take some time. From gathering materials to final assembly, it can take a few days to one week. It all depends on how well you know your tools and your DIY skills.

Common Mistakes When Building and Using a Bat Rolling Machine

Despite the straightforward nature of constructing a DIY bat rolling machine, several common errors can adversely affect the machine’s performance or lead to its premature breakdown.

- Using Incorrect Materials: One of the most common mistakes is using incorrect or substandard materials. Always ensure that your steel or aluminum, as well as other components, are of high quality and can withstand the stress of the rolling process.

- Improper Placement of Handles: The placement of the handles greatly impacts the functionality of your bat rolling machine. Incorrect positioning can result in inefficient operation and poor bat rolling results.

- Insufficient Lubrication of Bearings: The bearings, if not adequately lubricated, can cause friction and may wear out quickly, leading to machine failure.

- Incorrect Assembly: Incorrect assembly or installation of components can lead to malfunction.

- Forgetting Safety Measures: Another common mistake is neglecting to include safety measures such as protective gloves, safety glasses, or ear protection. These should always be used when operating the machine to avoid any accidents or injuries.

How Does The Rolling Machine Work?

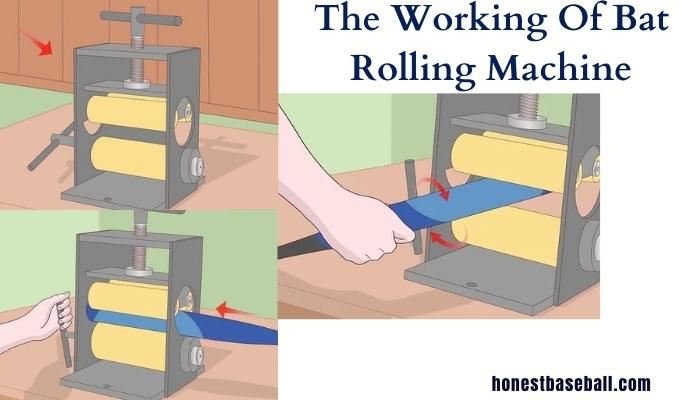

When going for the bat rolling service, the machine operator will position your composite softball or baseball bat into the rolling machine.

The bats should be compression tested for rolling. The compression test for the softball or baseball composite bats will help you to know the current break-in state before being rolled in.

So, you need to check the testing facility of the rolling service provider to hit the best result of the rolling service.

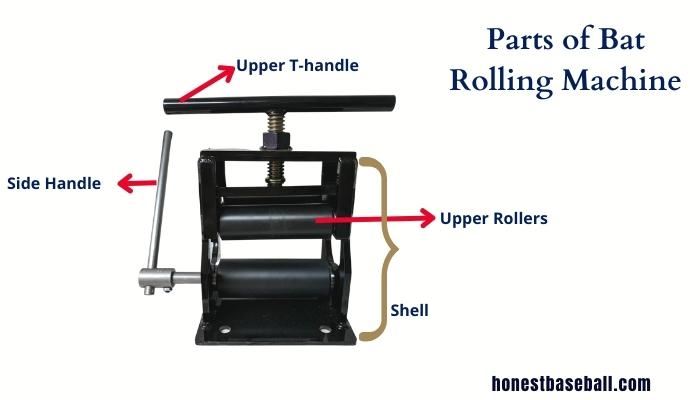

However, your new bat will be inside the rolling machine with two upper rollers and a single down roller on the machine.

There is an upper T-handle to adjust the upper roller position and pressure. Also, there is another side handle to reel your bat.

However, the roller machine could be automated as well. On the other hand, in a manual roller, you can rotate the bat by using the side handle.

The rolling will be basically on the sweet spot or hot spots of the abt to improve performance. The rolling softens the bats’ carbon fiber and makes it more flexible.

The rolling increases the trampoline effect and pop of the bat. This facilitates higher exit velocity. Also, this makes your bat game-ready.

The following video shows how an operator does the rolling on composite baseball bats.

Types of Bat Rolling Machines

There are two different types of rolling machines. One is Parallel, and another is Perpendicular. Let’s have a brief overview of them.

Parallel Rolling Machine

You will find two upper rollers and a single down roller in a parallel rolling machine. You need to insert the bats’ barrel into the machine parallel to the rollers.

After placing the bat’s barrel into the roller, the machine operator compresses the bat as per requirement. After this, the operator spins the bat handle, which rolls the barrel of the bat along with the rollers.

By the way, the rotation happens around 20 to 25 times. After being efficiently rolled, the bat gets a fast break-in, increased hitting power, and performance.

The rolling increases the exit velocity of bats. You don’t need to replace the bat in parallel rolling. The only drawback of parallel rolling is that almost the entire sweet spot is rolled at a time.

This may affect the natural break-in of the composite material of the bat.

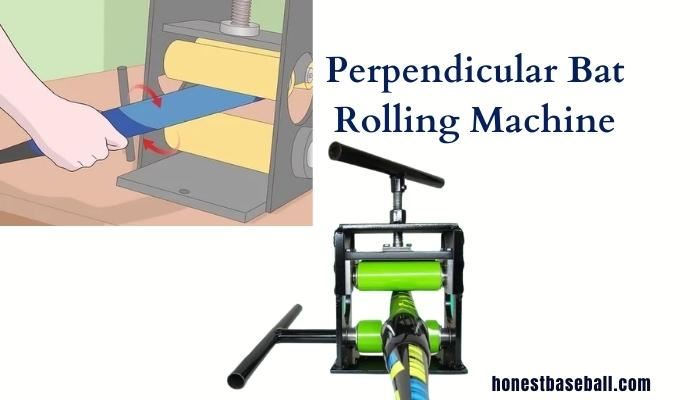

Perpendicular Rolling Machine

The perpendicular rolling machine allows you to insert your bat at a 90° angle. In this case, you can set the bat position back and forth.

During perpendicular rolling, you need to rotate the bat to cover the entire barrel and push and pull the bat front and back. Re-insert the bat and do the same process again till the process ends.

By the way, with each increment of barrel compression, you need to go through a minimum of 8 points. For this, you need to remove and re-insert the bat at least 4 times.

However, while using the perpendicular roller machine for increasing hitting power and break-in, you must be careful.

Excessive pressure and inefficient rolling may result in a flat spot on your bat’s barrel. This will surely decrease the quality of the rolled bat.

Excess rolling may alter the shape of the bats, which may not follow the legal use of bats. To avoid this, you may want to know which bats are illegal to use. Our following post on Illegal Baseball Bats – Models and Methods may be helpful to determine the illegal bats.

Maintenance Tips for Maximum Performance From Your Bat Rolling Machine

Owning a DIY bat rolling machine comes with responsibilities. Regular maintenance is paramount to keep your machine in top shape. Here are some tips.

1. Regular Cleaning: Ensure to clean your machine after every use. Dust and debris can cause unnecessary friction, affecting the lifespan of the components.

2. Lubrication: Keep those bearings well-lubricated. Increased friction can lead to wear and tear, affecting machine performance negatively. Regular lubrication ensures a smooth operation.

3. Tighten Fasteners: Regularly check and tighten all fasteners. Loose nuts, bolts, and screws can lead to malfunctions or even accidents.

4. Replace Worn-Out Parts: Monitor your machine closely. If any component, like a bearing or roller, shows signs of wear, replace it promptly. Early replacement prevents further damage.

5. Safety Checks: Always ensure to verify the safety measures before each use. This is for your protection

Does Bat Rolling Really Work For Composite Bat?

Yep, bat rolling is awesome for composite bats!

Here’s the deal – when a composite bat is made, the fibers are super tight. The more these fibers loosen up, the better the bat’s performance gets.

Usually, this “breaking in” process happens naturally as you use the bat. But that can take forever.!

That’s where bat rolling comes in. By rolling the bat in a machine, the fibers get compressed and loosened much faster and evenly. It’s like fast-forwarding the breaking-in process.

After rolling, your bat is ready to go and performs at its best right away. So, if you want to maximize your hit from day one, bat rolling is the way to go.

The Benefit Of Rolled Bat

There are many benefits to rolling a softball composite bat. Let’s see what they are.

More Power Generation

With a lot of contact with your bat and balls, the carbon fiber of the composite bats gets softened and flexible. This makes the bats more powerful and generates more power on the hit. And this happens gradually for a long time.

The same thing happens when you roll the bats. And yes, this happens in a short time. Ultimately, the rolled bats are able to generate more power hitting.

Dead Spots Removal

Dead spots are a common problem for used bats. Sometimes, some new bats also experience the same problem.

The dead spots of bats get recovered, and consistent contact of bats creates a natural pattern for great performance.

Larger Sweet Spot

In the wrap-out of the bat, the sweet spot lies in a particular space on the barrel.

The continuous pressing on the barrel while rolling breaks the carbon, making the barrel flexible. The entire barrel gets optimized for the sweet spot.

As a result, the barrel gets a larger sweet spot.

Quick Break-In

The difference between the bat that wraps out of the box and the rolled bat is its break-in state. Basically, the main focus of the bat rolling is to make the bat game-ready wrapped out of the box.

The rolling makes the bat game-ready with the fastest time in almost brand-new condition. Just grab and play extreme with your new bat.

Is Bat Rolling Illegal?

Bat rolling itself isn’t illegal, but it can be in certain situations.

Like in official league games, using a rolled bat can be considered against the rules and may lead to penalties. Most baseball and softball tournaments consider bat rolling illegal.

It’s seen as trying to gain an unfair advantage by boosting the bat’s performance beyond what the manufacturer intended.

So, while bat rolling can be a quick way to break in a new composite bat for practice or friendly matches, it’s important to know your league or tournament’s rules before using a rolled bat.

We have another detailed post concerning bat rolling and shaving. You will get a detailed discussion on the legality of rolling and shaving here. Check the Bat Rolling and Shaving for more.

Bat Rolling Machines For Sale

To be honest, bat rolling machines are expensive to buy. Generally, people who just need to roll their bats don’t need to buy a rolling machine.

Because it costs a lot, it won’t be worth it to roll 1 or 2 bats. I would say it will be a waste of money. The people who basically provide bat services for bat rolling machines are worth it for them.

Because it may cost you around $800 to $1500 to buy a machine.

The following are some of the best bat rolling machines.

- Extreme Black Legacy.

- ProRollers Patriot.

Baseball Bat Rolling Service

As buying a bat rolling machine is expensive, you can take the rolling service from renowned service providers.

Actually, it is the most cost-effective way to roll your bat perfectly. Because an efficient service provider will provide you with rolling through all previous welded design machines.

However, the rolling service may cost you $35 to $100.

Frequently Asked Questions

How To Make A Softball Bat Rolling Machine?

I have found a lot of questions about how to make a softball rolling machine. Actually, when you make the machine for a composite bat, there is nothing different about the softball.

What is the principle behind a bat rolling machine?

The principle of a bat rolling machine is simple. It applies pressure to the barrel of the bat, causing the composite fibers to compress and loosen, which effectively “breaks in” the bat faster than regular use.

Can I roll any type of bat in my DIY bat rolling machine?

No, bat rolling is mostly effective for composite bats. Aluminum or alloy bats do not benefit from bat rolling, and it might even cause damage.

How long does the bat roll process take?

The process itself is relatively quick, often taking a few minutes. However, the length of time can vary depending on the bat’s material and age.

Does the bat rolling machine damage the bat?

If done correctly, bat rolling does not damage the bat. However, over-rolling or incorrect use of the machine can cause harm to the bat.

Is There Performance Improvement With Bat Rolling?

While there’s no guarantee that bat rolling will magically boost performance, it does make sure that your bat will have an awesome ‘pop.’ This means the bat will give a better rebound effect when it hits the ball, potentially sending it flying farther

Does Rolling a Bat Shorten Its Life?

Bat rolling, when done correctly, does not necessarily shorten the lifespan of a composite bat.

It simply accelerates the break-in process that normally occurs over time with regular use. However, over-rolling or improper use of a bat-rolling machine can potentially damage the bat, which can lead to a shortened lifespan.

Does Bat Rolling Void Warranty?

Just a heads up, bat rolling can amp up the performance of a composite bat, but it usually voids the manufacturer’s warranty.

Most bat makers have this thing in their warranty terms. Any changes to the bat’s original state, like rolling, cancel out the warranty.

Wrapping Up

Buying a bat rolling machine is not a wise decision, but you can get the service for a cost-effective rate. Because purchasing it will cost a lot, which will not be worth it.

However, you can also make your own machine at home if you are an expert in making such devices.

But, it is wise to get the service if you are not skilled enough to make such a machine. Also, be careful about the alteration.

Because if the bat gets altered because of rolling, it will be illegal to play in leagues.

You Might Also Like:

How To Roll A Bat Without A Machine

How To Build A Round Portable Pitching Mound

Hello everyone. My name is Jason Butler, and I live in California, America. I was a professional AAA Minor League Baseball player. I lost my chance of playing MLB for injury issues, but I did not lose my love for baseball. I attended the coaching training program and am now working as a coach in a small school in San Diego.

I always love to share my experience and knowledge if that can help you. Play baseball, and stay fit.