Last Updated on November 28, 2023

Have you ever tried to count how many stitches are on a Baseball? Don’t there are many, and they are on both sides.

I used to know that from childhood. My father was a baseball freak. Thank you, Dad, for introducing me to the wonderful game, and I am making my living now from this game.

So, how many stitches are on a major league baseball ball? Why are the stitches red, and how do the stitches of baseball balls evolve? Let’s find out some interesting history.

How many Stitches are on a Baseball?

Let’s get to the point directly.

There are a total of 216 stitches on the seams. But those are not on the side. An official major league baseball consists of 108 double-sided stitches. The first and the last stitches remain hidden on the baseball.

The core of the ball is made of two figures and eight patterns of cowhide. These pieces are sewn and then passed into the rolling machine to complete the pitches.

MLB baseball manufacturers use a waxy red thread to stitch the ball, which has become the standard since 1998.

Do Stitches Affect The Performance Of A Pitch?

The number of stitches on a baseball can affect the ball when it’s played, well, anything, really. Stitches spin and drag the ball, which can determine things like pitch, speed, and trajectory.

A high stitch count results in more control over the ball but makes it slower. This is good for pitchers who want to pull off curveballs and sliders.

On the other hand, fewer stitches make the ball go faster with less air resistance but leaves little control over its direction.

However, the effect of stitch count is subtle and generally less significant than factors such as the pitcher’s skill and the weather conditions.

So, while it does play a part in performance, it’s not something you’ll want to rely on solely for great results.

The number of stitches on a ball will also affect how it looks and feels. More stitches will lead to a rougher surface, unlike balls with fewer stitches.

How Many Stitches on MLB Baseball?

There are 108 double-stitched MLB baseballs or 216 individual stitches sewn with red cotton thread in each one. This method is meant to keep things fair between all major league games.

This small thing can make all the difference in feel, too, as we mentioned before.

How do they make Baseball?

- Rubber and cowhide are the two main materials that make a baseball.

- First, they use two rubberized hemispheric shells and attach the rubberized cork to that. Then, they use rubber gaskets to fill the space between the shells.

- Then, it’s time to create the core. They mold a red layer to cover the rubber, which creates the core or, technically, which is called a “pill.”

- After finalizing the shape, they use a thin layer of cement on the surface. This is a crucial step before they use the cowhide to make the real ball.

- Major league baseball management has specific requirements for the size of the ball. Manufacturers need to use computerized machines to maintain the shape and weight of the ball.

- Two hundred wool yarns are tightly wrapped around the ball.

- Then comes the final step. Here, manufacturers use the winding process to wrap the wool yarn with white finishing yarn. Then, they use the cowhide and stitch to complete the baseball.

Do you know the weigh of a baseball? Even if you do, you might be wrong. But not after reading this article on How much does a baseball weigh?

Baseball Stitching Process

Two figures – 8 patterns of cowhide leather are used to cover each half of the baseball.

They are temporarily attached to the surface of the ball. Manufacturers use a special type of solution and submerge the cowhide. This process helps the cowhide to manipulate and mold.

Sadly, machines are not great enough to complete the baseball stitching process. Therefore, the human hand is required to complete the stitching. The hand-stitching process is still used.

Manufacturers use red thread on the cowhide to stitch the ball. Then, a rolling machine is used to make the stitch and cowhide exterior surface even.

Then, they run a final quality test, and if the baseball meets all the requirements, they enter the market.

Are baseballs still stitched by hand or Machine?

Don’t be surprised! In spite of new technology and manufacturing methods developed over time, making production easier than ever, people still stitch every single baseball by hand.

Each Major League Baseball will have its own personal stitcher dedicated to stitching balls together. It was done this way since God knows when, so there’s no real reason to change.

Plus, doing it by hand ensures that quality is maintained and provides a level of charm you just couldn’t see otherwise.

Why does Baseball need to be Stitched?

The stitches on baseball have many practical reasons. You can not grip a baseball perfectly with just the cowhide. The following are the reasons why stitching is necessary for baseball.

- Gripping: This is the first reason why an official baseball should be stitched. The higher number of stitches makes it easier for the pitchers to hold the ball on hand and inside the glove.

- Pace: Baseball is made of several layers. The rubber center, inner cork, and the external leather from the cow make up the ball with wool yarn. The stitch connects all of those. You can look at lemon peel balls and will get the point.

- The Swing: The Boston Red Sox pitcher showed that the baseball’s stitching could change the orientation when the ball flies. They showed in the national league how the ball’s trajectory changes using the sim or stitch.

- Controlling the speed: If you are a pitcher, you must know changing the speed is vital, or you will be out of the park. The stitches help pitchers to control the speed of the ball.

- Appearance: The stitching contributes to the distinctive look of a baseball. A ball with more stitches will have a rougher and more textured surface, adding to its aesthetic appeal.

- Durability: Finally, the stitches hold the two pieces of cowhide (known as the baseball cover) together, ensuring the ball’s longevity and durability.

Why are Baseball Stitches Red?

Red and white are contrasting colors.

Therefore, batters can pick the spin of the ball easily. In the previous section, I have told how pitchers use the stitches to grip and change the flying direction of the ball.

So, it will be very tough for the batters if they can not identify the spin of the ball. The red color helps hitters to identify the spin of the ball.

But the ball was not as it was. In the early 1900s, MLB baseballs in the national leagues were made of red and black laces. On the other hand, the American League used blue and red stitches.

In the 1990s, the American League Baseball changed the standard. In that year, they decided red would be used to stitch baseball. Since then, manufacturers have been maintaining these rules.

Do you know which bats are illegal and how a bat becomes illegal in a baseball match?

Baseball Stiches Vs Softball Stiches

Baseballs have 108 double-stitched or 216 individual stitches tightly packed, leaving them only slightly above their surface dyed red, which makes them easy for pitchers to grip and control.

On the other hand, softballs have fewer stitches, at around 88 double stitches or 176 individual stitches. These are more prominent and far apart than baseballs, which are often dyed red or white.

In a way, this gives a pitcher a different kind of grip with the increase in size and prominence of those stitches.

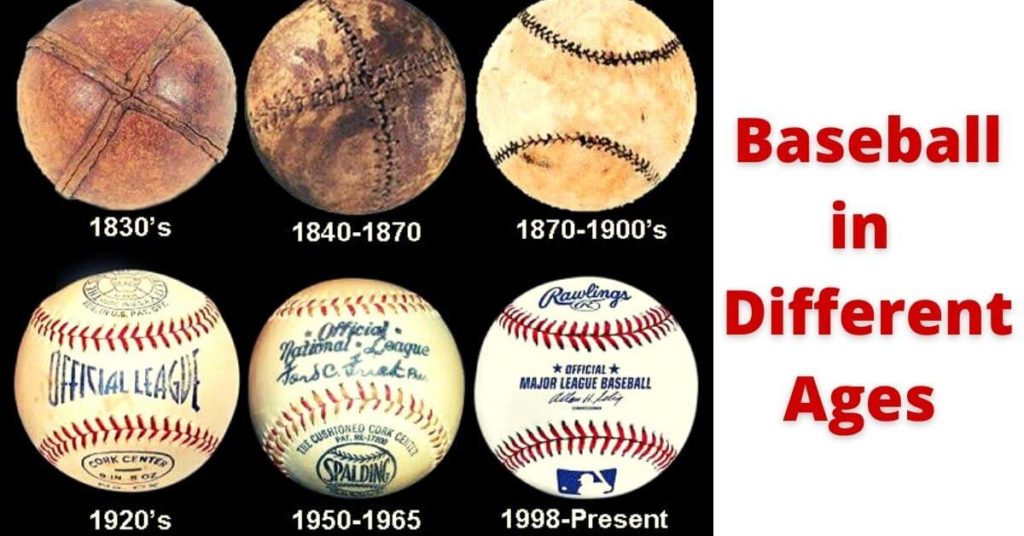

History of Baseballs

Now you know how many stitches are on a baseball and some other important things. Now let me tell you some history of baseball.

Manufacturers used to provide baseballs with different shapes, weights, and sizes. Baseball is not that famous these days. Therefore, batters used to make their own bats, and pitchers used to make baseballs.

Do you want to know how to make a wooden baseball bat at home?

Okay, come to the point again. The baseballs that pitchers used to make were known as lemon peel balls. The term was introduced because of its roughness and bumpiness. As no standard was set then, the balls were of different sizes and shapes.

So, since when do all baseballs come in the same shapes? It was in the year 1876 when all balls were bound to be of the same size.

Another interesting piece of information is they used horsehide to manufacture baseball instead of cowhide until 1974.

A.G. Spalding, a famous Red Sox pitcher, pursued professional baseball clubs to use his baseball in the tournament.

The National League committee got his point, and his baseball became the official ball until 1976. You can learn that from

Then MLB changed their mind and offered Rawlings Sporting Goods to manufacture baseballs for them in 1976. Since then, they have been the official baseball manufacturer of the major leagues.

You might be also interested in the History of baseball and we have also a list of the 100 greatest baseball players.

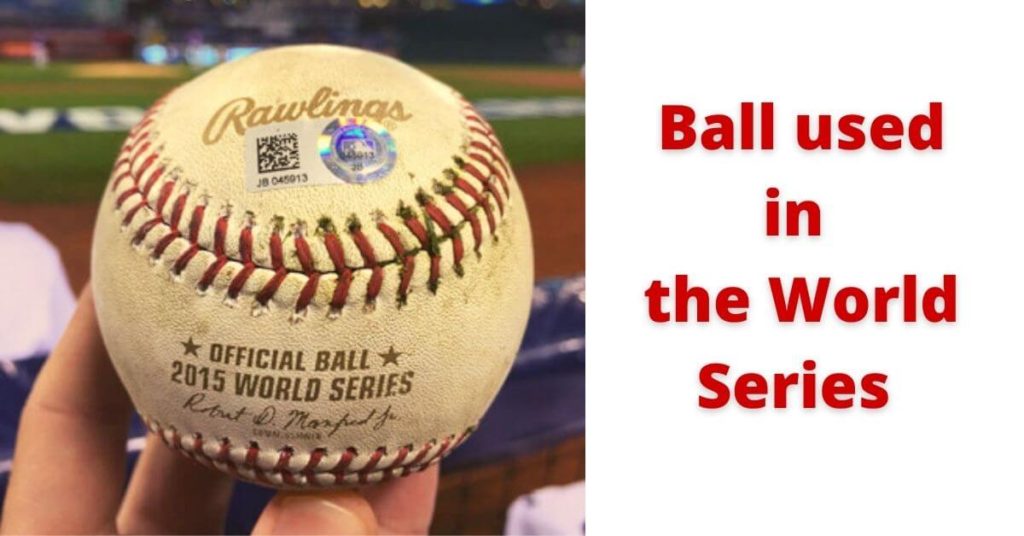

Is there Any Special Baseball?

Yes, there are some special baseballs used on special occasions. Major league baseball management uses special baseballs to celebrate some occasions during the season.

Some of the occasions are the All-Star Game, Home Run Derby, World Series, and some other occasions that the major league wants to make special.

How do they make the balls special? If you closely observe, you will see special stamps are used on those balls. Sometimes, MLB management uses different colors in the stitches. For example, the color of the All-Star game baseball is different.

Do they Replace the Baseball during the Game?

Hundreds of baseballs are used in a particular baseball match. But how on earth are so many balls needed in a particular baseball match?

Have you ever been to a baseball field? If the ball goes to the stand, that ball does not come out. Spectators on the field can retain the ball when it goes to the gallery for home runs or foul balls.

Another vital reason is the lifespan of baseball. Baseball gets dirty too early. If the ball becomes dirty, umpires can review the ball and make the decision whether the game will be continued with that ball or not.

If the umpire thinks the baseball is too dirty to play for the infield dirt, they can change the ball and get a new one.

It doesn’t matter what the reason is. If a baseball gets out of the field, that ball will not come back to the field in any case.

Another reason is the safety of the batter. A very sad incident happened in 1920 at the Polo Ground. Ray Chapman was hit on the head with a baseball and was hospitalized, and at last, he passed away.

Since then, umpires have been very sincere about the sight of baseball. If it looks too dirty and the batter feels any discomfort watching, they replace that. Remember, baseball pitchers in the MLB are really fast.

Do you want to know how you can increase your pitching velocity by 10 mph?

Moreover, if the ball is new and shines, spectators can see the match clearly. That is another reason many balls are used in a particular match.

Related Interesting posts:

Do major league baseball players wear new jerseys every match?

Do MLB umpires pay for their travel?

Frequently Asked Questions

Who makes Major League Baseball?

Though there are many famous companies that make baseballs, MLB purchases their balls from one single company with an exclusive contract. Since 1976, MLB has been purchasing their baseballs from Rawlings. But it’s not mandatory for other tournaments to buy from Rawlingtons.

There are many other brands that make top-quality baseball. Some of the top baseball equipment manufacturers are Marucci, Easton, Wilson, etc.

Does the USA produce Baseball?

The USA used to manufacture baseballs. But the vast majority of baseballs are made in China. However, MLB baseballs are not manufactured in China.

Rawlings manufactures major league baseballs, and they manufacture their baseballs in Costa Rica.

What is the Manufacturing Cost of Baseballs?

Well, no manufacturer reveals the manufacturing cost of any product. However, I read an interesting article on the CBC news on the manufacturing cost of baseballs.

According to them, the official manufacturer of major league baseball, Rawlings, is around $4. Remember, how many balls are required in a single MLB match?

One hundred! As the demand is very high, Rawlings has to provide a huge quantity of them.

And MLB purchases those balls from them at USD 7 apiece. And in the retail store, they are sold at USD 15.

I hope you can get an idea about other manufacturers manufacturing the cost of their baseballs.

Want to read some baseball bat reviews? We have some great bat reviews for you:

- Cat 7 BBCOR Reviews | Side By Side Details

- Marucci F5 Reviews & Comparison With Others (Best in Budget)

- CAT 7 Vs CAT 8 BBCOR – A Complete Comparison

- Easton Beast Pro Drop 5 Review

- Louisville Slugger Solo 618 BBCOR Review

Wrapping Up

So, now you do know how many stitches are on a baseball. There are 108 double stitches on a baseball, which is 216.

I hope you now have other interesting information on baseball. If you are new to baseball, you must be interested in knowing the terms DFA, FPS, WHIPS. Cycle, ERA.

These are very interesting terms many new baseball fans don’t know.

Hello everyone. My name is Jason Butler, and I live in California, America. I was a professional AAA Minor League Baseball player. I lost my chance of playing MLB for injury issues, but I did not lose my love for baseball. I attended the coaching training program and am now working as a coach in a small school in San Diego.

I always love to share my experience and knowledge if that can help you. Play baseball, and stay fit.