Since I started playing baseball, I have been in love with the game. It was too exaggerated for me to get a proper glove always. Searching for where to find the best baseball glove, I found out the best way how to make a baseball glove.

It is crucial to learn how your baseball glove is made; that is how you can understand the difference between a good glove and a lousy glove. Hence, following my guide can help you understand more about baseball gloves.

In this guide, I will elaborate on the materials and tools used to make a baseball glove, step-by-step how to make a baseball glove and many more interesting facts.

Essential Baseball Glove Parts to Know About

Before I tell you about the baseball glove manufacturing process, it is vital to learn the parts. In fact, it is necessary to know all the parts of the baseball glove before manufacturing it properly, or else your manufactured glove can not be top-notch.

Here are all the baseball glove parts –

- Web: The webbing of a baseball glove is an integral part of its construction, serving both functional and aesthetic purposes. It is typically constructed of leather, although synthetic materials may sometimes be used.

The web is typically a diamond or H-web shape, providing a pocket to catch the ball and protect the hand. Its design also gives the glove a distinct style, making it a vital part of the overall appearance.

The glove webbing is stitched together using a variety of stitching patterns, depending on the brand, model, and material used. The stitching can also be customized for a player’s hand size or preference.

- Palm: The palm of the baseball glove is a crucial part of the glove’s construction. It serves as the primary point of contact between the ball and the glove and is responsible for protecting the hand of the fielder.

The palm of the glove should be made of a complex, durable material that will protect the needle from the ball’s impact and provide a secure grip. In some cases, an additional layer of padding may be added to the palm of the glove for extra protection.

- Wrist Adjustment: If the wrist adjustment is not set well, the glove will undoubtedly fall off, or you may not feel the glove comfortable. D-rings and buckle systems allow you to tighten and loosen your gloves anytime.

- Heel: The bottom end of the glove’s palm is known as the heel. I usually call it the hen of the gloves. You will find it near the joint between your hands and arms. It protects the wearer’s wrist and hand.

- Lacing: Another essential part of the glove. It helps to shape the glove properly. Without the lacing, your glove will not be properly wearable. Lacing is made of leather because of the break-in.

Materials and Tools

The tools and materials I used to make the baseball glove were good! With proper furnishing, I made my glove smooth, comfortable, and long-lasting. A good glove can make an enormous difference in performance and comfort.

Raw Materials to Make a Baseball Glove

When I first tried making my baseball glove, I was slightly surprised. I got the glove manufactured better than I expected. Here are the raw materials I used to make the glove –

- Plastic,

- Nylon,

- Leather (Cowhide, kangaroo hide, etc.).

When I saw the manufacturer build it, it felt so easy. The manufacturer combined the nylon and the plastic to buckle up the thumb and the fingers. The remaining part of the hand was made of leather. I used kangaroo hide as the leather because it was soft and easy to break in.

Do you know how to break in a baseball glove? It is easy and can be done in 5 minutes!

Tools to Make a Baseball Glove

Creating a high-quality baseball glove requires precision and the right tools. You can make a baseball glove easily with the right set of tools. When I made my baseball glove, the manufacturer used many tools. Here is the list for you –

- Knife,

- Dies,

- A glue gun,

- Stitching machine,

- An awl,

- A hammer,

- A pair of scissors.

All the tools here have their unique usage. With proper crafting, you can make the best baseball glove for yourself.

How Long Does It Take to Make a Baseball Glove?

While custom gloves can add up all the features you want, it has one wrong side. It takes a considerable chunk of time than regular baseball glove manufacturing. Generally, the average time to make a quality baseball glove is between 8-10 hours.

This includes the time spent cutting and sewing the leather, attaching the laces and linings, and finally, shaping the glove. Once I had a match, and I needed a custom glove so severely.

I went to the manufacturer to ask for the fast delivery of a custom baseball glove that perfectly fit my hand. But for this latency, I had to wear another glove, leading me to play one of the worst matches in my life.

Hence, if you want to have a custom baseball glove, make sure you already have a good alternative to it.

How to Make a Baseball Glove

I have made it step by step to break the whole process down. I still remember how a renowned manufacturer created my first custom glove. If you go through this entire process, you can make your custom and comfortable baseball glove too.

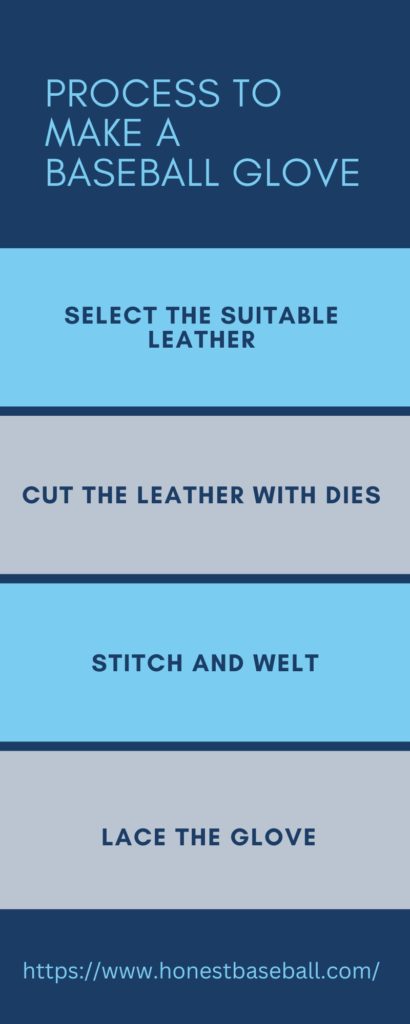

Step 1 – Select the Suitable Leather

Leather selection is essential when creating the best baseball glove. If you are a professional, you already know what I meant. When playing baseball for a long time, learning how to sustain your glove damage is essential, while providing excellent comfort is essential.

When I made my glove, the manufacturer used kangaroo hides to make the leather. They told me that it is the most comfortable and long-lasting leather. I tried it, and the feeling was amazing! You can use cowhide for your leather too.

Cowhide is softer than kangaroo hide. So, I do not recommend you use it. But it depends on how you want to make your baseball glove.

Step 2 – Cut the Leather with Dies

When my manufacturer made the gloves, he took the hides to make a perfect glove shape. To do that, he used cutting dies. This is the best way to make a glove with perfect measurements.

Cutting dies to create specific shapes, which is essential to crafting gloves. Can you imagine more than 20 pieces of leather are needed to make a single glove?

Step 3 – Stitch and Welt

Creating a baseball glove requires a combination of stitching and welding techniques, which I will firmly tell you to follow. After you have made all the pieces of the hide with perfect measurements, follow these points –

- Prepare the welting material by cutting it into strips of the desired length.

- Line up the leather pieces and use a stitching machine to sew them together.

- Before completing stitching, stuff the welting material in between the two pieces of leather and finish the stitch.

- Finally, use a welting machine to add a decorative stitch to the edges of the glove for a more finished look.

Step 4 – Lace the Glove

I prefer leather lace as the glove is also made of leather. This will provide comfort and a secure binding between the web and the glove.

There are many other options for laces too, but I will not suggest them. If you are looking for comfort, you should definitely go for leather laces.

Also, if you are thinking of stiffening your glove, do not worry. First, finish manufacturing your custom glove, then you can quickly stiffen up your glove.

Why Make My Own Baseball Glove?

I will always find a solution when I am in a problem. Similarly, when I was looking for a suitable baseball glove, I was not satisfied with any of the sizes. Either the size was too big or too small, or I wouldn’t say I liked the shape.

At that time, I thought about making my custom glove. I looked at how the gloves were correctly manufactured and found a manufacturer who was polite in making my glove. He took the sizes and shapes of my hand, the glove, and so on.

When I wore the finished good, I was so surprised that I was amused. It was so comfortable and fit! I was enjoying my plays too.

Here are some of the reasons why I think you should make your custom baseball glove too –

- A customized glove allows you to choose the glove’s size, shape, color, leather-type padding, and other features that make it unique.

- With a custom glove, you can create the perfect glove for your playing style, hand size, and field conditions.

- Custom gloves are often more durable and have a better fit and feel than their off-the-shelf counterparts.

- Additionally, a custom glove can be a great way to express your style and be a statement piece on the field.

- With a custom glove, you can step onto the field feeling confident and ready to perform your best.

Frequently Asked Questions

1. What Materials Are Baseball Gloves Made of?

Generally speaking, most baseball gloves are made from various materials, including leather, synthetic leather, and other fabrics.

Leather is the most common material used to make baseball gloves due to its durability and comfort. Gloves made from full-grain leather can last long and offer excellent protection.

However, they can be expensive and may require regular maintenance. Synthetic leather is another popular option.

2. How Much Leather Does It Take to Make a Baseball Glove?

The amount of leather needed to make a baseball glove can vary, depending on the size and shape of the glove.

Generally, an adult-sized glove requires 6-7 ounces of leather, while a youth-sized glove requires 3-5 ounces. The leather used to make a glove is usually cowhide, though some higher-end gloves may use kangaroo leather.

The leather must be cut into the appropriate pieces for the glove’s components, such as the palm, webbing, and fingers.

3. What Is the Strongest Leather for Gloves?

Full-grain leather is typically the most durable and robust option, as it is made with the entire grain of the hide. This type of leather also typically has more character and depth due to its natural grain pattern.

Top-grain leather is the second-most common type of leather used for gloves. It is more durable than split-grain leather and is generally considered the most popular glove choice.

Final Thoughts

It can be an observing matter of how to make a baseball glove. If you are not confident enough to wear a glove from a company, follow the process I mentioned in this article.

I think with the help of a good manufacturer, you can make the best glove fit for your baseball games. Make sure you are not manufacturing the glove a day before your games.

Lastly, make sure your gloves are correctly fit. Provide the actual measurements of your hands, or else the produced glove will not be suitable for the hand.

Hello everyone. My name is Jason Butler, and I live in California, America. I was a professional AAA Minor League Baseball player. I lost my chance of playing MLB for injury issues, but I did not lose my love for baseball. I attended the coaching training program and am now working as a coach in a small school in San Diego.

I always love to share my experience and knowledge if that can help you. Play baseball, and stay fit.